PP plastic suction nozzle

PP plastic suction nozzle

Crystalline material, low hygroscopicity, difficult to produce melting body break, long time to take cold metal war difficult synthesis.

Liquidity depends, but the scope of expansion and expansion value is large, it is difficult to produce shrinkage cavity.Indentation, distortion.

The cooling rate is fast, the casting system and cooling system should disperse the cold quickly, and the forming temperature should be carefully controlled.When the material temperature is high temperature and low pressure, it is difficult to be oriented. When the mold temperature is below 50 degrees, there is no lubrication for the plastic parts, and it is difficult to generate welding without good, flow mark, and warping deformation is difficult to be generated above 90 degrees.

Plastic wall thickness should be even to avoid lack of glue and sharp Angle to prevent stress convergence.

PP polypropylene, with high impact resistance, strong mechanical temper, but also resistant to a variety of organic solvents and acid and base decay.It is widely used in industry。

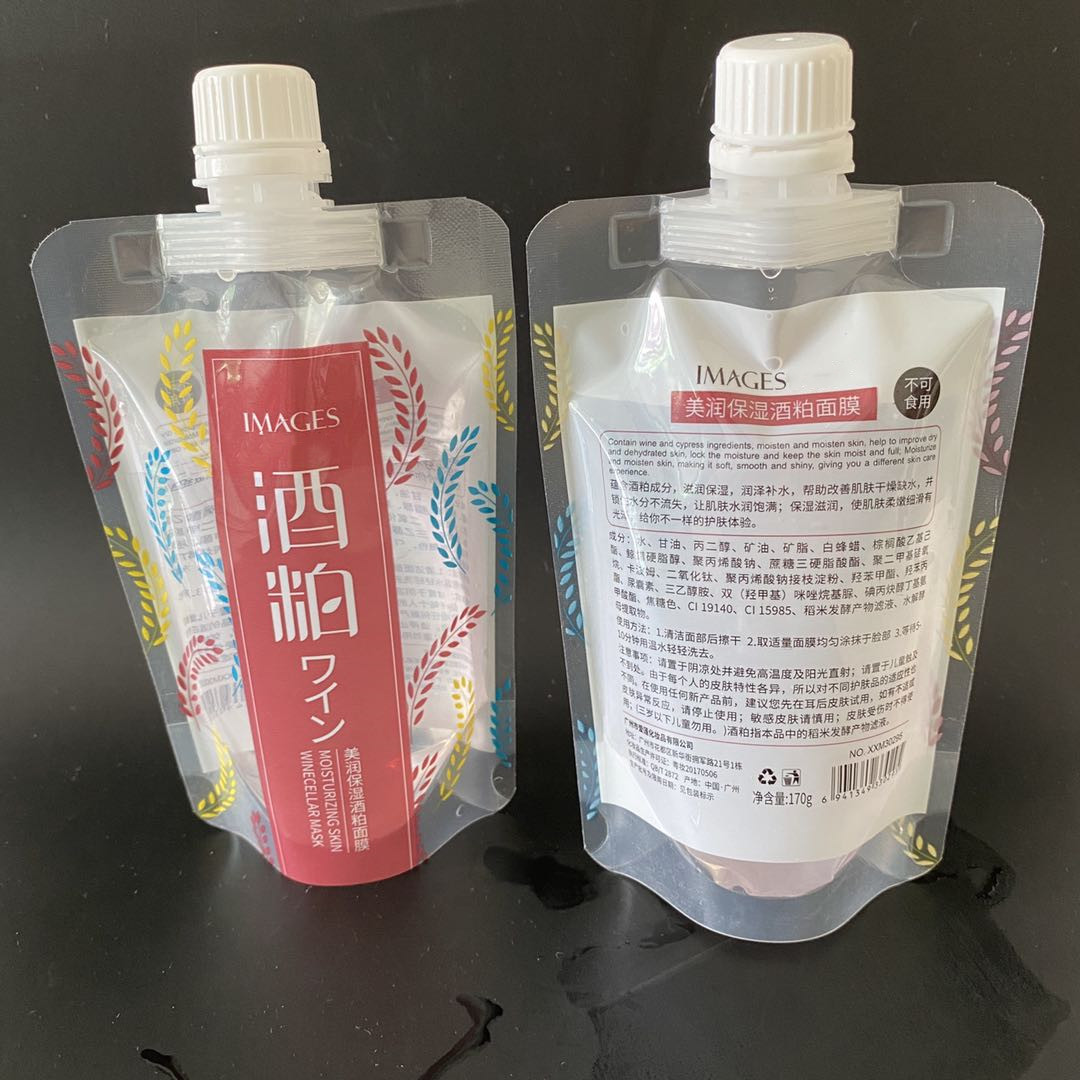

PP plastic suction nozzle is mainly used in some cosmetic industry and industry.For example, facial mask, detergent, dishwashing liquid and so on。